Common problems in the welding process! Welder must collect

Welding defects can be divided into internal defects and external defects according to their position in the weld.

External defects are located on the outer surface of the weld and can be seen directly. External defects mainly include weld size that does not meet the requirements, undercut, weld bead, collapse, surface pores, surface cracks, burn-through, etc.

Internal defects mainly include incomplete penetration, internal pores, internal cracks, slag inclusion, etc. Internal defects located inside the weld must be found by non-destructive testing or destructive testing.

Causes of welding defects

1. Weld

The weld size does not meet the requirements. Mainly refers to the welding seam is uneven, different in width, and the remaining height is too high or insufficient.

Too small weld size will reduce the load-bearing capacity of the welded joint; too large weld size will increase welding workload, increase welding residual stress and welding deformation, and cause stress concentration.

Improper welding groove angle or uneven assembly gap, excessive or small welding current, improper method or speed of welding, and improper welding angle, etc., will cause the weld size to fail to meet the requirements.

2. Undercut

When welding, the groove formed at the junction of both sides of the weld and the base metal is called undercut (or bite). The undercut will reduce the effective cross-section of the base metal and weaken the strength of the welded joint. At the same time, the undercut is prone to stress concentration, which may cause cracks at the undercut after loading, and even cause structural breakage.

The cause of undercut is improper operation process and incorrect selection of welding specifications, such as excessive welding current, excessive arc, and improper welding rod angle.

3. Welding

During the welding process, the metal nodules formed by the molten metal flowing to the unmelted base metal outside the weld are called weld nodules. The weld bead not only affects the appearance of the weld, but also often has incomplete penetration defects under the weld bead, which is easy to cause stress concentration. Excessive welding seam gap, incorrect electrode position and transportation method, excessive welding current or too slow welding speed, etc. will all cause welding bead.

4. Burn through

During the welding process, the molten metal flows out from the back of the groove, and the defect that forms a perforation is called burn-through.

The main reason for burn-through is that the welding current is too large and the welding speed is too slow. Burn-through will also occur when the assembly gap is too large or the blunt edge is too thin.

5. Not fused

Unfused refers to the part between the weld bead and the base metal or between the weld bead and the weld bead that is not completely fused together; or refers to the part where the base material and the base metal are not completely fused together during spot welding.

The reasons for the lack of fusion are that the welding line energy is too low; the arc blows sideways; the sidewall of the groove has rust and dirt; the welding layer is not completely cleaned.

6. Dimples, collapses and underfills

The pit refers to the local low-lying part formed on the surface of the weld or the back of the weld, which is lower than the surface of the base metal.

Collapse refers to the phenomenon that due to improper welding process during single-sided fusion welding, excessive weld metal permeates through the back side, which causes the front side of the weld seam to collapse and the back side to bulge. Due to insufficient filler metal, continuous or intermittent grooves formed on the surface of the weld are not filled.

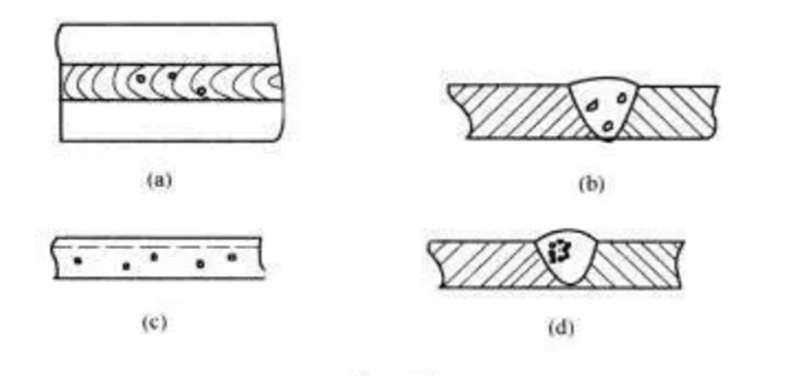

7. Slag inclusion

The slag remaining in the weld after welding is called slag inclusion.

There are many reasons for the occurrence of slag inclusion, such as the edges of the weldment, the welding layer, and the weld bead. The welding current is too small, which causes the melting to accelerate the solidification speed, and the slag does not have time to emerge; improper transportation, slag and molten iron Unclear separation prevents the slag from floating; the chemical composition of the weldment and electrode is improper; the molten pool contains too much oxygen and nitrogen.

8. Stoma

During welding, the bubbles in the molten pool fail to escape during solidification and the remaining cavities are called pores. Stomata can be divided into dense stomata, worm-like stomata and needle-like stomata. The gas that forms pores in the weld is mainly hydrogen, nitrogen, and carbon monoxide.

Porosity has a greater impact on the performance of the weld. It not only reduces the effective area of the weld and reduces the mechanical properties of the weld, but also destroys the compactness of the weld and is easy to cause leakage.

The reasons for the pores are that the good protection of the welding zone is damaged during the welding process; the base material welding zone and the surface of the welding wire have oil stains, rust and contaminants that adsorb water; the welding rod is damp and the baking is insufficient; the welding current is too large or too small , The welding speed is too fast; the welding arc is too long and the arc voltage is too high.

9. Crack

The temperature at which welding cracks are formed can be divided into hot cracks and cold cracks, and can be divided into cracks in the weld metal and cracks in the heat-affected zone according to where the cracks occur. In the welding process, the weld cracks produced when the weld and heat-affected zone metal are cooled to the high temperature zone near the solidus line are called hot cracks; the weld cracks produced when the welded joint is cooled to a lower temperature are called cold cracks.

Welding cracks are the most dangerous welding defect, which seriously affects the performance and safety and reliability of the welded structure. In addition to reducing the strength of the welded joint, the crack also has a sharp notch at the end of the crack, which will cause serious stress concentration and promote the development and destruction of the crack.

Using our company’s all-position automatic pipe welding equipment can effectively avoid the above problems. Please contact our service staff for more relevant information.

Post time: Aug-03-2021